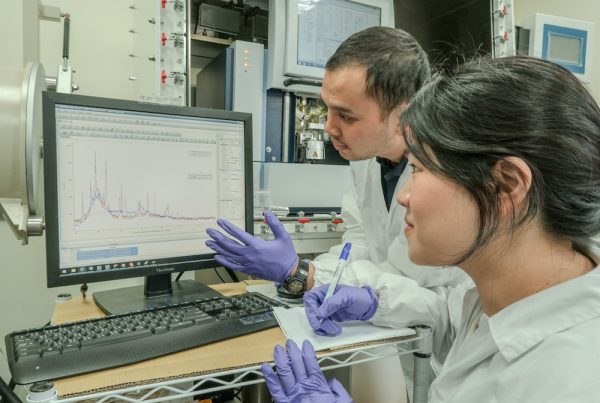

The challenge of implementing Li-ion battery on a real life is try to combine two features, high safety and high performance, all together. Here we realize the possibility of combining both features in Li-ion battery through researches we are conducting.

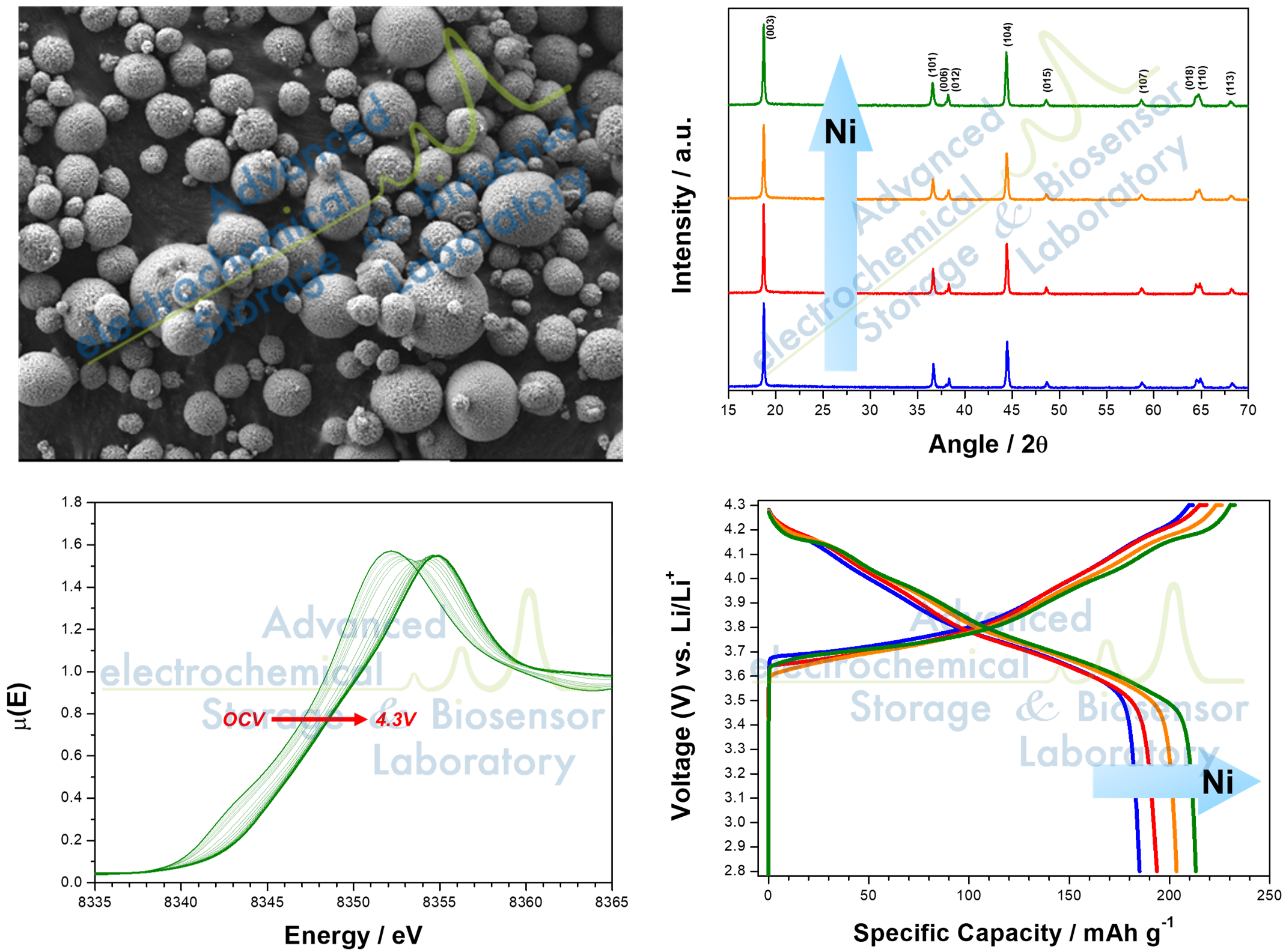

High-capacity Ni-rich cathode material.

Researchers love to push the technology to the edge. Here we evaluate the structure, electrochemical performance, and the safety of layered Ni-rich cathode material containing Ni more than 80% which is known for having a high capacity. Such XRD, SEM, XPS, XAS, and other techniques are conducted to understand the layered Ni-rich cathode material from the material point-of-view. Meanwhile, galvanostatic cycling and the in-operando techniques (such XANES, gas pressure, GCMS, FTIR, XRD) are performed to figure out the correlation of the electrochemical and the material characteristics. These techniques contribute to better understanding on how to bring closer to high safety and high-performance Li-ion battery.

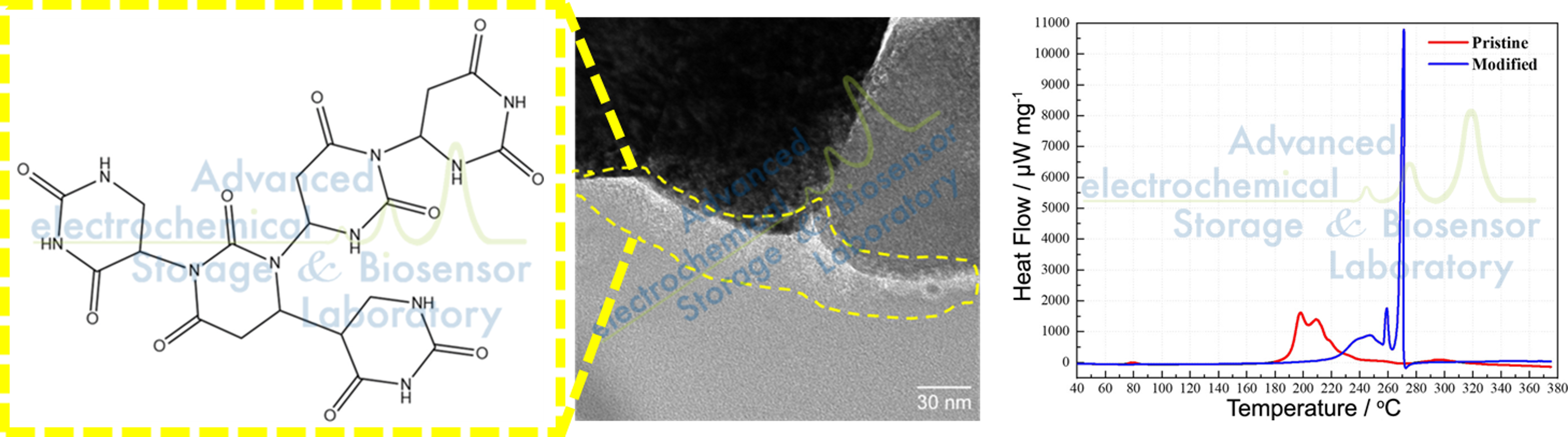

Organic coverage.

We are developing an organic compounds to enhance safety and performance of the cathode material. We previously reported polymerized pyrimidine derivatives as an organic coverage on layered Ni-rich cathode material which gives an excellent safety and performance. In addition, this organic coverage is simply added during slurry making. In this development process, the combination of various monomer or polymer with the pyrimidine derivatives are explored.

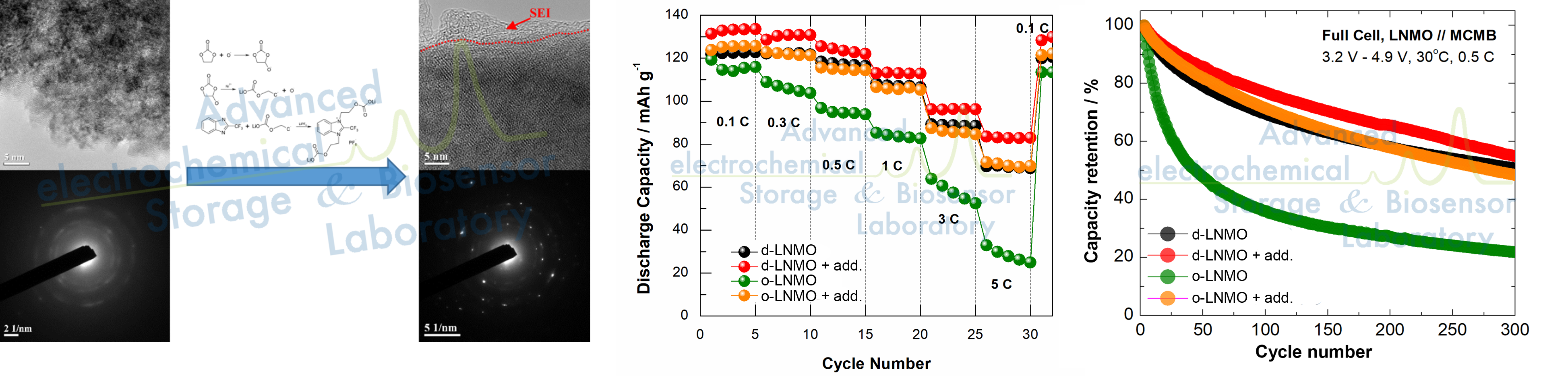

High Voltage (>4.5V) Cathode Material.

Li-ion batteries with high power and high energy density are required to satisfy users for a long driving range of electric vehicles. Theoretically, high energy density can be achieved by increasing the cut-off charging voltage of cathode materials. Spinel LiNi0.5Mn1.5O4 and Li-rich LNMO are promising candidates for the high-voltage cathode material due to the redox reaction of Ni2+/4+ at above 4.7 V. However, the main issue of the high voltage application is the electrolyte decomposition especially the decomposition of the LiPF6 and carbonate-solvent electrolyte. In addition, the transition metal dissolution from the spinel LNMO cathode is another issue in spinel LNMO.

Herein, we develop the salt additive electrolyte to overcome the issues. Preventing the LiPF6 decomposition reduces the HF formation in the electrolyte and prevents the transition metal dissolution. Furthermore, the salt additive electrolytes can improve the cycle stability of the high-voltage cathode materials.

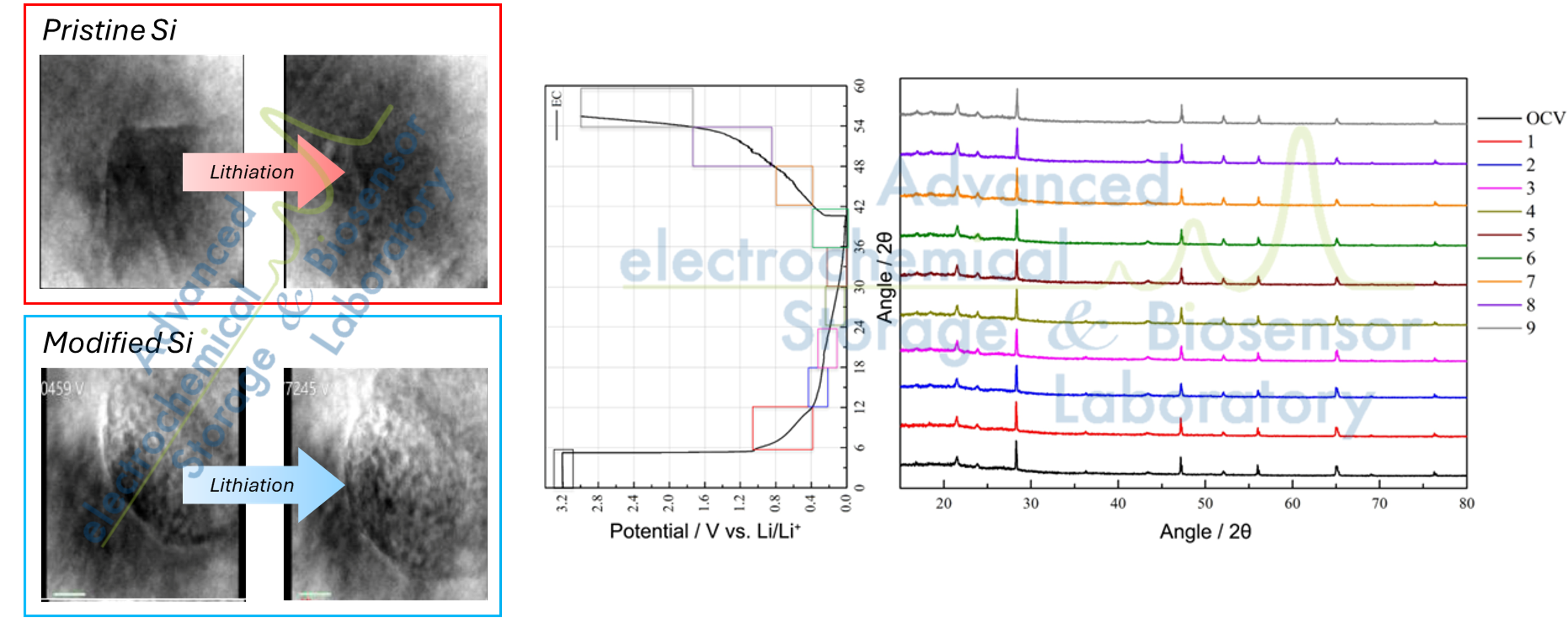

Silicon anode materials.

Silicon anode draws a significant interest for the Li metal replacement due to its high capacity (~3580 mAh/g), low reduction potential nearly 0 V, and its abundancy in earth crust. These characteristics of Si improve the energy and volumetric density of Li-ion battery. However, a large volume changes and severe SEI formation worsen the battery’s safety and performance. Surface modifications are explored in our research group to alleviate these problems. We are also do an exploration to reuse the silicon which is originating from the other manufacturing process (such solar cell, microchip, etc.). The in-operando facilities (XRD, FTIR, GCMS) provide better understanding on the correlation of material and electrochemical characterizations of silicon.

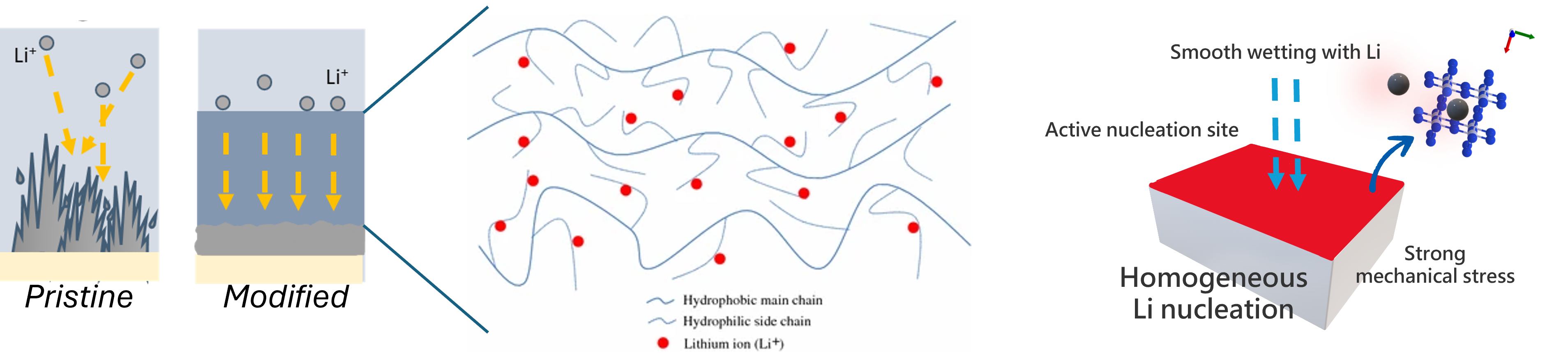

Anode Less and Anode Free Lithium Metal Battery.

Lithium metal is considered as a “holy grail” anode material for Li-ion battery due to its high capacity, low reduction potential, and it has a light weight. However, improve the safety and cycle life of lithium metal are the main important task. To answer the challenge, we are conducting research on the concept of anode less and anode free lithium metal battery. These concepts allow a significant improvement on the volumetric capacity of the Li-ion battery. We currently are trying to enhance the lithium deposition uniformity on the current collector, both 2D and 3D type, by using plasma treatment and or lithiophilic polymer with a unique lithium diffusion pathway.

Related publications:

- Evaluation of LiNiO2 with minimal cation mixing as a cathode for Li-ion batteries. Link: https://doi.org/10.1016/j.cej.2022.141065

- Investigations of an organic coverage to Ni-rich cathode materials: Effects on deteriorated, cathode electrolyte interphase, and chemical crossover. Link: https://doi.org/10.1016/j.est.2024.112184

- Preventing the Distortion of CoO6 Octahedra of LiCoO2 at High-Voltage Operation of Lithium-Ion Battery: An Organic Surface Reinforcement. Link: https://doi.org/10.3390/polym15092211

- Improvement in the electrochemical stability of Li[Ni0.5Co0.2Mn0.3]O2 as a lithium-ion battery cathode electrode with the surface coating of branched oligomer. Link: https://doi.org/10.1016/j.surfcoat.2020.126121

- In Situ Co–O Bond Reinforcement of the Artificial Cathode Electrolyte Interphase in Highly Delithiated LiCoO2 for High-Energy-Density Applications. Link: https://pubs.acs.org/doi/10.1021/acsami.1c13523

- Controlling Ni2+ from the Surface to the Bulk by a New Cathode Electrolyte Interphase Formation on a Ni-Rich Layered Cathode in High-Safe and High-Energy-Density Lithium-Ion Batteries. Link: https://pubs.acs.org/doi/full/10.1021/acsami.0c22295

- Interface Interaction Behavior of Self-Terminated Oligomer Electrode Additives for a Ni-Rich Layer Cathode in Lithium-Ion Batteries: Voltage and Temperature Effects. Link: https://pubs.acs.org/doi/full/10.1021/acsami.9b12123

- Robust Benzimidazole-Based Electrolyte Overcomes High-Voltage and High-Temperature Applications in 5 V Class Lithium Ion Batteries. Link: https://pubs.acs.org/doi/full/10.1021/acs.chemmater.7b00824

- Failure Mechanisms of High-Voltage Spinel LiNi0.5Mn1.5O4 with Different Morphologies: Effect of Self-Regulation by Lithium Benzimidazole Salt Additive. Link: https://pubs.acs.org/doi/full/10.1021/acssuschemeng.2c06845

- Investigation of space group effects of High-Voltage spinel LiNi0.5Mn1.5O4: Unveiling the influences of fluorinate benzimidazole salt additive. Link: https://www.sciencedirect.com/science/article/pii/S1385894724044759

- Investigations of Intramolecular Hydrogen Bonding Effect of a Polymer Brush Modified Silicon in Lithium-Ion Batteries. Link: https://doi.org/10.1002/admi.202102007

- Tailoring of a reinforcing and artificial self-assembled alkyl sulfonic acid layer electrolyte interphase on silicon as an anode for high-energy-density lithium-ion batteries. Link: https://doi.org/10.1016/j.electacta.2022.140489

- The development of super electrically conductive Si material with polymer brush acid and emeraldine base and its auto-switch design for high-safety and high-performance lithium-ion battery. Link: https://doi.org/10.1016/j.electacta.2022.140829